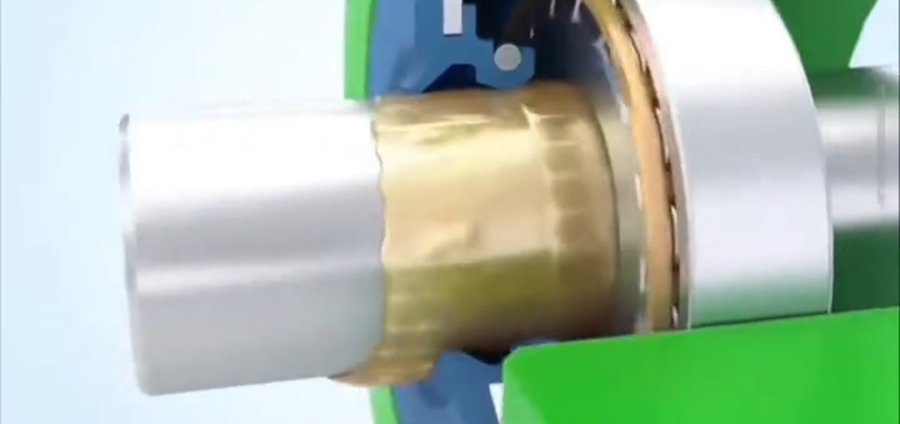

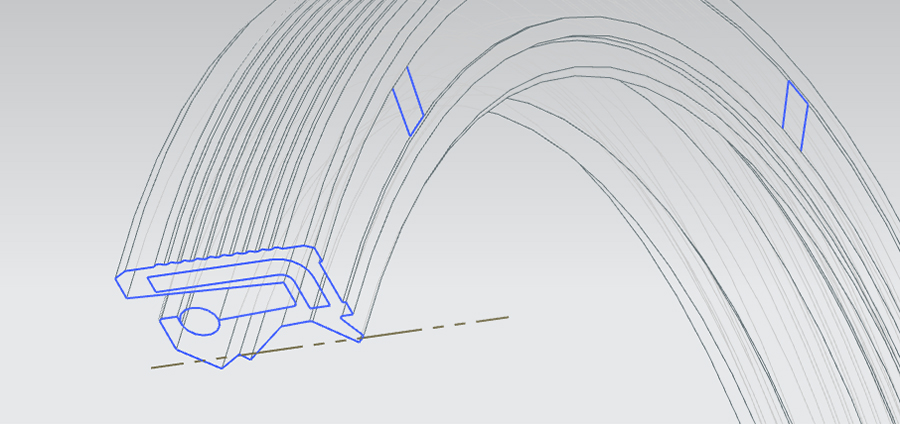

The skeleton oil seal is an important element in the mechanical system used to isolate lubricating oil and grease and prevent their leakage. Usually installed on the shaft of mechanical components, through its lip-shaped structure and elastomer material, forming a sealing barrier to prevent impurities such as iron filings, water and dust from intruding into the mechanical interior, thus protecting the normal operation of mechanical equipment. The operation of the oil seal is not completely reliable, the existence of itself and the influence of many peripheral factors. So what are the reasons for the problems of oil seals in operation? How to deal with it?

【Oil seal failure phenomenon】

Part.1 Oil-spill

This is the most common manifestation of oil seal failure. Can be observed in the oil seal installation parts of the oil seepage, may be in the form of drops, may also gradually form oil droplets converge into oil flow, resulting in oil stains around the equipment, not only a waste of oil resources, but also may contaminate the surrounding environment, affecting the overall cleanliness of the equipment, and in serious cases, may even lead to safety hazards, such as in the presence of open flames and other specific environments, the leakage of the oil is prone to cause fires and other accidents.

Part.2 Increased wear and tear

Oil seal lip and the sealed shaft diameter and other parts of the mating parts of excessive wear, intuitively manifested in the oil seal lip roughness, breakage and so on, the sealing surface is no longer smooth and flat, and at the same time with the surface of the shaft diameter may also produce scratches, wear traces, etc., which will further undermine the sealing effect and may be accompanied by abnormal friction sound, affecting the smoothness of the equipment operation.

Part.3 Aging, hardening or softening of rubber

Oil seals are generally made of rubber, the failure of rubber aging may occur, manifested as darker, lose elasticity, hard and brittle texture, easy to crack; or soft and sticky situation, so the sealing performance of the oil seal will be greatly reduced, can not effectively block the leakage of oil, and the aging or deterioration of the rubber is easy to fall off the crumbs, mixing into the oil may also cause oil pollution, affecting the entire lubrication system and the normal work of the related components. The normal work of the entire lubrication system and related components.

【Reasons for Oil Seal Failure】

Part.1 Installation

◆Improper installation: If an improper tool is used to install the oil seal, or the operation technique is incorrect, such as exerting too much force, it may lead to the deformation of the oil seal, so that its original sealing structure will be damaged, and it will not be able to fit the sealing surface, so that there will be leakage and other failure problems. For example, the use of sharp tools to pry the oil seal, easy to scratch the lip of the oil seal.

◆ Inaccurate installation position: the position of oil seal installation is deviated, not accurately installed to the specified shaft diameter or cavity position, resulting in uneven gap between the oil seal and mating parts, some places are sealed too tightly, while some places are not sealed tightly, so that the oil is easy to seep out of the parts that are not sealed tightly.

Part.2 Environmental aspects of use

◆Temperature too high or too low: Extreme temperature environment has a great influence on the rubber material of oil seal. In high temperature environment, rubber is easy to accelerate aging and lose elasticity, for example, in the engine and other high-temperature running parts around the oil seal, if long time in the working conditions beyond its tolerance temperature range, the oil seal will soon fail; and low temperature environment will make the rubber hard and brittle, reduce its flexibility, easy to produce cracks, resulting in seal failure.

◆Chemical corrosion: If the oil seal is in the environment of corrosive gases and liquids, for example, in some chemical equipments, the oil contains corrosive components or there are corrosive gases such as acidity and alkalinity in the surrounding air, the rubber of the oil seal will be corroded and then lose the sealing ability.

Part.3 Component Matching Aspects

◆ Inappropriate surface roughness of the shaft diameter: If the surface of the shaft diameter is too rough, it will accelerate the wear of the lip of the oil seal and damage the sealing surface prematurely; while the surface is too smooth, it may lead to the inability to form a good oil film between the lip of the oil seal and the shaft diameter, resulting in dry friction, which also damages the oil seal and affects the sealing effect.

◆ Improper size coordination: the size tolerance between the oil seal and the shaft diameter, cavity and other matching parts is unreasonable, the gap is too large, the oil is easy to leak through the gap; the gap is too small, the oil seal will be installed too tight, resulting in excessive friction, leading to heat, wear and tear of the oil seal, and ultimately failure.

Part.4 Oil seal quality

◆ Poor rubber material: the use of poor quality rubber raw materials to produce oil seals, the aging resistance, abrasion resistance and other properties can not meet the requirements, in the normal use of the process will be faster aging, breakage and so on, can not guarantee the long-term effective seal.

◆ Defective manufacturing process: In the manufacturing process of oil seals, such as imperfect vulcanisation process, inaccurate lip shaping, etc., which may cause uneven internal structure of oil seals, bubbles and other quality problems, reducing the overall strength and sealing performance of the oil seals, and easy to be ineffective after being put into use.

【Analysis of measures】

Part.1 Installation session

◆ Standardise the installation operation: Use professional installation tools and adopt correct installation methods according to the requirements of installation instructions provided by the equipment manufacturer, such as using suitable jigs and fixtures to install the oil seal in place slowly and smoothly to avoid unnecessary damage and deformation of the oil seal.

◆ Inspection before installation: Before installing the oil seal, carefully check the cleanliness of the installation part, the surface condition of the shaft diameter and whether there are any defects of the oil seal itself, etc., to make sure that all the aspects meet the installation conditions, and deal with the non-compliance in time, such as cleaning the installation cavity and repairing the scratches on the surface of the shaft diameter.

Part.2 Improvement of use environment

◆Temperature control: For the equipment working in high temperature environment, heat insulation measures can be adopted, such as installing heat insulation cover to reduce the influence of external high temperature on the oil seal; in the low temperature environment, special oil seal materials with low temperature resistance can be considered, or the equipment can be preheated appropriately, so as to make the oil seal work in the appropriate temperature range.

◆Anti-corrosion treatment: In the environment with chemical corrosion risk, choose the oil seal material with corresponding corrosion resistance, and at the same time, do a good job of sealing protection for the equipment as a whole to prevent the external corrosive medium from contacting the oil seal, but also can be cleaned regularly on the oil seal and the equipment, to remove the corrosive substances adhered to it.

Part.3 Optimisation of component fit

◆ Ensure the quality of shaft diameter: process the surface of shaft diameter reasonably, make its roughness reach the standard range, and ensure the cylindricity and other shape and position tolerance of shaft diameter meet the requirements, so as to provide a good matching surface for the oil seal.

◆Precise selection and matching: according to the actual working conditions and design requirements of the equipment, accurately select the oil seals with suitable size tolerance to ensure that the matching gap between the oil seals and the shaft diameter and cavity is reasonable, which can ensure good sealing and will not affect the life of the seals and the sealing effect due to over-tightening or over-loosening.

Part.4 Oil seal quality control

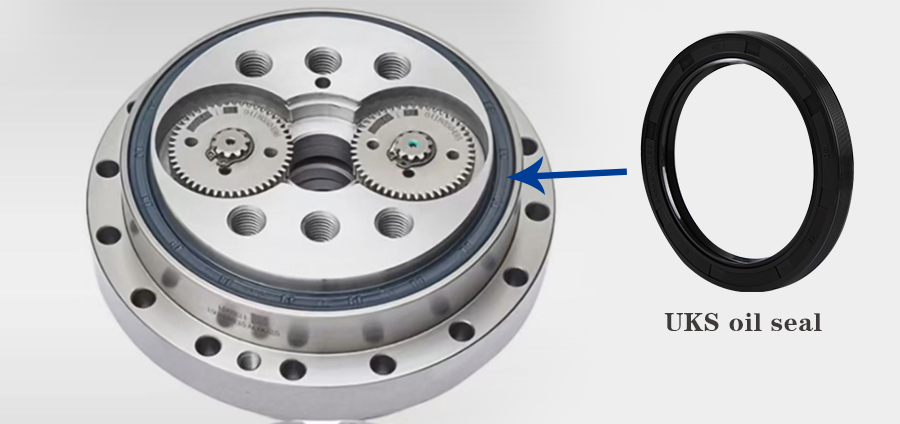

◆Choose high-quality products: Purchase oil seals from regular and reputable suppliers, give priority to products of well-known brands and in line with relevant quality standards, check the quality certification and other information of the oil seals to ensure that they are made of excellent rubber materials and advanced manufacturing processes. High-quality UKS seals must be recognised for purchase from licensed distributors.

◆Quality inspection: After the arrival of oil seals, carry out the necessary quality sampling, through the appearance of the inspection, dimensional measurements and simulated working conditions of the sealing performance test and other means, eliminate unqualified oil seal products, to ensure that the installation of the oil seals used to ensure the reliability of the quality of oil seals.

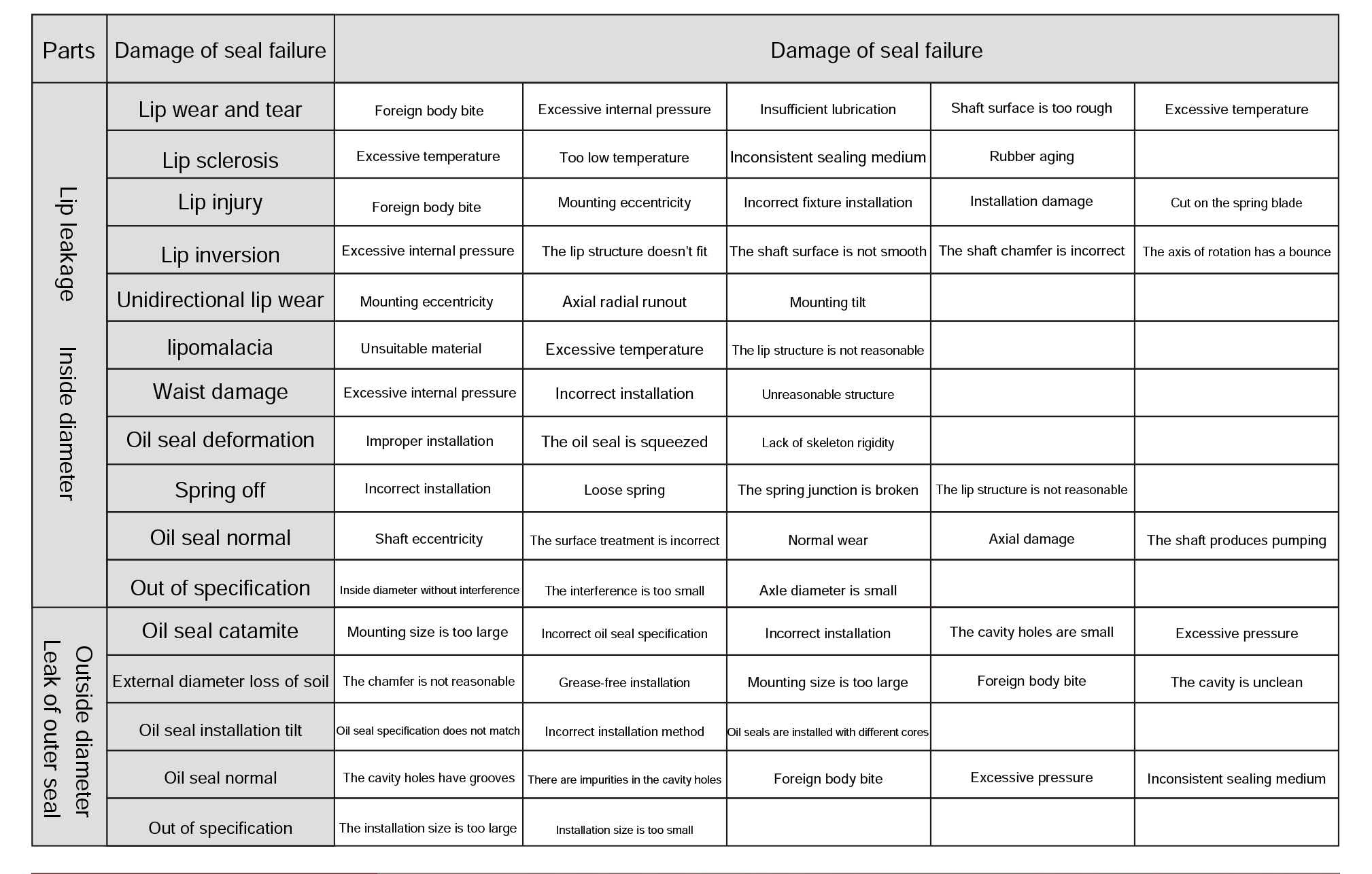

Oil Seal Failure Possibilities Quick Check Chart

In short, oil seal failure is a problem involving many factors, need to be installed, the use of the environment, parts with the quality of the oil seal itself and other angles of comprehensive analysis and take appropriate effective measures to protect the good sealing performance of the oil seal to extend its service life, to ensure the normal and stable operation of the equipment.